You’ll find nitrous oxide serving essential roles across diverse industrial applications. It’s utilized in semiconductor manufacturing for precise oxidation processes, automotive performance augmentation for power gains of 50-200 HP, and metal fabrication for preventing oxidation during welding. You’ll also see it in food processing for texture improvement and cryogenic freezing, plus aerospace propulsion systems. The compound’s unique chemical properties make it invaluable for numerous advanced industrial processes still being uncovered.

Understanding the Chemical Properties of Nitrous Oxide

While commonly known for its anesthetic properties, nitrous oxide (N₂O) exhibits distinct chemical characteristics that make it valuable for industrial applications. You’ll find it exists as a colorless gas at room temperature, with a slightly sweet odor and a density 1.5 times that of air. The compound’s thermal stability requirements demand careful monitoring, as it can decompose explosively when heated beyond safe thresholds. At elevated temperatures, the gas becomes increasingly reactive and participates in more chemical reactions. Semiconductor manufacturers rely on N₂O during the oxidation process to create high-quality silicon dioxide layers.

Industrial safety concerns center on N₂O’s oxidizing properties and storage conditions. Though nonflammable itself, it supports combustion and releases oxygen radicals that can relight glowing splints. You’ll need high-pressure tanks maintained above 750 psi for proper storage, along with sophisticated leak prevention systems. The gas’s behavior in augmented temperatures makes it particularly useful in semiconductor fabrication, where controlled decomposition aids in defect repair. As a greenhouse gas threat, N₂O has approximately 300 times the warming potential of carbon dioxide, requiring strict emission controls in industrial settings.

Applications in Automotive Performance and Racing

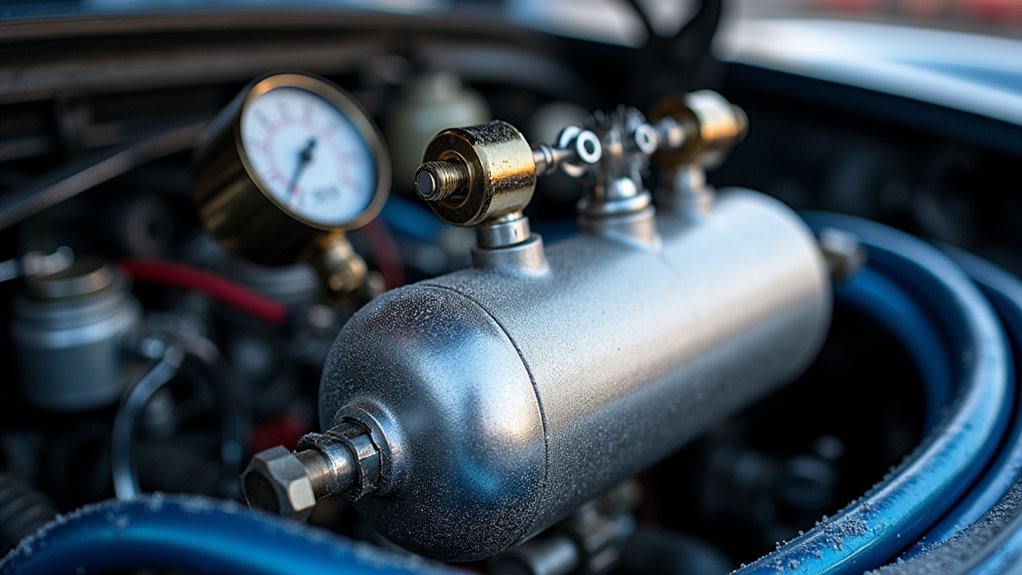

Nitrous oxide’s industrial applications extend powerfully into automotive performance, where its oxidizing properties serve a specialized purpose in racing and high-performance vehicles. The liquid N2O undergoes a process where it splits at 570°F to release additional oxygen for combustion. You’ll find both dry and wet injection systems available, with integration with engine electronics allowing precise control over tuning parameters for maximized performance. A vital pre-run check includes system purging to ensure proper liquid nitrous delivery.

These systems can amplify horsepower by 50-200 HP, offering a cost-effective alternative to turbocharging or supercharging. When you’re implementing NOS, you’ll need to verify your engine components can handle the increased stress. Proper installation requires high-quality components to ensure safe and reliable operation.

Modern systems feature real-time monitoring and adaptive delivery mechanisms that maintain ideal air/fuel ratios while preventing dangerous detonation. While banned for street use in some areas, NOS remains prevalent in motorsports, where its ability to deliver instant power surges proves particularly valuable in drag racing applications.

The Role in Modern Electronics Manufacturing

In the semiconductor industry, you’ll find nitrous oxide playing a vital role in chemical vapor deposition (CVD) processes, where it facilitates the growth of high-quality dielectric films on silicon wafers.

The gas enables precise oxidation reactions during the formation of silicon dioxide layers, which serve as essential insulators in integrated circuits and microprocessors. The process increasingly involves thin-film oxides made with titanium, aluminum, and other elements to enhance device performance. Due to its chemically inert properties, nitrous oxide provides stable and controlled reactions during semiconductor fabrication. Manufacturers rely on ultra high purity nitrous oxide with 99.999% composition to ensure optimal results.

Your clean room gas management systems must maintain strict purity standards for N₂O delivery, as even minor contamination can compromise the integrity of semiconductor devices during manufacturing.

Semiconductor Processing Innovations

Modern semiconductor manufacturing has revolutionized electronics through advanced processing techniques that rely heavily on nitrous oxide’s unique chemical properties. N2O functions with deposition gases like silane in critical manufacturing steps. You’ll find nitrous oxide playing a vital role in nitride layer engineering, where it’s used to create high-quality silicon nitride films essential for advanced transistor designs. The process requires ultra-high purity to maintain device performance and yield. Continuous nitrogen purging helps prevent contamination during the manufacturing process.

The gas enables precise control of dielectric properties through plasma nitridation processes, particularly in forming Si₃N₄ and SiON layers. These innovations allow you to achieve superior gate insulation and reduced leakage currents in CMOS devices.

When combined with CVD techniques, nitrous oxide facilitates the deposition of ultra-thin films with precisely controlled thickness and composition. This capability’s particularly valuable in memory device fabrication, where you need exact dimensional control for creating protective coatings and ensuring reliable data retention in semiconductor components.

Clean Room Gas Management

Effective cleanroom gas management builds upon the precision requirements of semiconductor processing by implementing sophisticated control systems for particle-free environments. You’ll find these systems maintain ISO 14644-1 compliance through precise temperature control (±1°C) and advanced filtration achieving 99.97% efficiency with HEPA filters. Modern facilities require strict gowning procedures to prevent contamination when personnel enter gas management areas. The focus on contamination control has intensified with the passage of the CHIPS Act funding, driving greater investment in cleanroom technologies.

Managing inert gas storage and controlling chemical vapor dispersion are critical components of cleanroom operations. You’ll need to implement positive pressure differentials to prevent external contamination while utilizing gravity-based exhaust systems for residual process gases. Polypropylene materials are essential for gas management systems due to their resistance to chemical exposure.

The integration of continuous particle monitoring guarantees cleanliness standards remain within ISO 5-8 classifications for electronics manufacturing. Within these controlled environments, you’ll maintain strict entry protocols and process segmentation to isolate gas-sensitive operations, protecting critical components from oxidation and moisture exposure during fabrication.

Culinary and Food Processing Uses

Nitrous oxide serves four primary functions in culinary and food processing applications: texture improvement, preservation, cryogenic freezing, and fermentation control. You’ll find this versatile gas creating stable foams in confectionery formulations, ameliorating ice cream textures, and elevating foodie experiences through molecular gastronomy innovations.

In preservation applications, N2O disrupts microbial growth through rapid freezing and creates inert atmospheres for packaged foods. The gas’s cryogenic properties enable quick-freeze technology that prevents ice crystal damage while maintaining product integrity.

When controlling fermentation, N2O accelerates yeast activity in bread making and promotes uniform flavor distribution in wine and cheese production.

This gas’s precision in portion control and texture manipulation has revolutionized both commercial kitchens and artisanal food preparation, particularly in aerated sauces, frozen desserts, and specialty beverages.

Aerospace and Rocket Propulsion Systems

Aerospace engineers have turned to nitrous oxide as a game-changing propellant in rocket systems, capitalizing on its unique self-pressurizing properties and improved safety profile. You’ll find this propellant replacing hazardous cryogenic propellant systems, particularly in small satellite applications where safety and simplicity are paramount.

| Feature | Benefit |

|---|---|

| Non-toxic nature | Simplified ground operations |

| Catalytic decomposition | Reliable ignition control |

| In situ resource utilization | Reduced launch costs |

The technology’s maturation has led to widespread adoption, with over 50 operational thrusters across 12 satellites. You’ll see specific impulse ratings of 238 seconds in kerosene/nitrous oxide configurations, making it competitive for diverse space applications. Modern designs like the M-420 engine showcase the propellant’s effectiveness through integrated catalyst beds and regenerative cooling systems, delivering 420 lbf of thrust while maintaining high reliability and performance.

Metal Fabrication and Welding Processes

Moving from space propulsion to industrial applications, nitrogen gas – not nitrous oxide – plays a central role in metal fabrication and welding processes. You’ll find nitrogen consumption trends increasing across TIG, MIG, and laser welding operations due to its superior shielding properties. When you’re working with reactive metals like titanium or stainless steel, nitrogen prevents oxidation and maintains material property improvements throughout the fabrication process.

The gas’s versatility extends beyond basic welding. You’ll achieve cleaner cuts in laser operations, minimize post-weld cleaning requirements, and guarantee consistent microstructure development during cooling. In modern facilities, you can generate nitrogen on-site, reducing reliance on cylinder supplies while optimizing cost efficiency. This approach delivers superior weld quality and supports advanced fabrication techniques where precise atmospheric control is pivotal.

Chemical Manufacturing and Industrial Synthesis

You’ll find nitrous oxide playing a vital role in the production of nitric acid through catalytic oxidation processes, where it serves as both a reaction intermediate and oxidizing agent.

In fertilizer synthesis applications, N2O participates in complex nitrogen fixation reactions that help create essential agricultural compounds like ammonium nitrate and urea-based products.

The controlled decomposition of nitrous oxide in these manufacturing processes requires exact temperature and pressure conditions to maintain ideal reaction kinetics and product yields.

Nitric Acid Production Process

The industrial production of nitric acid centers on a multi-stage process that converts ammonia to nitric acid through careful control of oxidation and absorption reactions. In this process, you’ll find platinum-rhodium catalysts operating at 800-1000°C to convert NH₃ to NO, with careful catalyst poisoning management essential for maintaining efficiency. The NO then oxidizes to NO₂, which absorbs into water to form HNO₃.

Modern facilities typically employ dual-pressure systems, which optimize both the oxidation and absorption stages while maximizing reaction heat recovery. You’ll see absorption towers using sieve or bubble cap designs to achieve acid concentrations between 55-65%. The most efficient plants can produce up to 1,000 tons daily, utilizing advanced emission controls and scrubbers to minimize NOₓ releases.

Fertilizer Synthesis Applications

Recent advances in N₂O conversion technologies have revolutionized fertilizer synthesis applications, offering an environmentally conscious alternative to traditional nitric acid-based production methods. You’ll find that this breakthrough process converts N₂O directly into potassium nitrate through mechanical pounding and salt mixture reactions, bypassing fossil fuel-dependent ammonia oxidation steps.

This novel approach supports efficient fertilizer production while enabling mitigation of agricultural emissions. The process captures and binds N₂O gas over approximately six hours, creating agriculturally usable nitrates. You’re looking at a dual benefit: reducing the 75% contribution of N₂O to agricultural greenhouse emissions while recycling waste gases into valuable fertilizer components.

Engineers are now scaling these technologies for industrial implementation, incorporating nitrification inhibitors and optimized application rates to optimize nitrogen efficiency and minimize environmental impact.

Safety Protocols and Handling Requirements

Strict safety protocols govern the industrial handling of nitrous oxide due to its unique decomposition risks and oxidizing properties. When handling this medical gas, you’ll need to follow key practices across two critical areas.

Initially, maintain proper material compatibility by using oxygen-compatible lubricants, keeping surfaces clean to oxygen standards, avoiding contaminants, guaranteeing proper valve maintenance, and using approved valves and fittings like ball valves.

Secondly, implement thermal and pressure controls by avoiding high-temperature processes, operating below propagation thresholds, using pump interlocks to prevent dry running, and controlling adiabatic compression through slow valve opening. These industrial storage requirements help prevent decomposition incidents and safeguard the handling of this potentially hazardous gas.

Environmental Impact and Sustainability

Understanding nitrous oxide’s environmental footprint reveals considerable climate and atmospheric concerns that demand immediate attention. With a global warming potential 273 times higher than CO₂ and atmospheric persistence of 114 years, N₂O markedly accelerates climate change. It’s also a leading cause of ozone depletion through NOx emissions.

Industrial applications, medical anesthetic adoption, and dairy farm waste mitigation efforts must address the 6% contribution to U.S. greenhouse emissions. You’ll find over half of purchased N₂O is lost during storage and transport, while healthcare facilities experience substantial leakage during anesthesia delivery.

To combat these issues, organizations are implementing mobile destruction units, centralized decomposition systems, and advanced recycling technologies. Real-time N₂O detection and agricultural waste management strategies offer promising solutions for reducing environmental impact.

Future Industrial Applications and Innovations

Dynamic innovations in nitrous oxide applications continue reshaping multiple industries as technological advancements drive new use cases. Promising production methods through catalyst optimization and amplified purification techniques are revolutionizing manufacturing efficiency. You’ll find expanding healthcare demand driving development of portable delivery systems and specialized medical applications.

| Industry | Innovation | Market Projection |

|---|---|---|

| Healthcare | Smart delivery systems | $1.72B by 2025 |

| Automotive | Hybrid power solutions | 5.9% CAGR |

| Chemical | Advanced catalysts | $1.6B by 2025 |

| Manufacturing | Automated processes | 10.2% growth |

These developments signal significant shifts in industrial applications, with semiconductor manufacturing and precision engineering leading technological breakthroughs. You’re seeing rapid advancement in automated production systems, while medical applications expand into specialized treatment protocols and augmented pain management solutions.

Frequently Asked Questions

How Much Does Industrial-Grade Nitrous Oxide Cost per Unit Volume?

You’ll find industrial-grade N₂O wholesale pricing varies based on your order volume and storage requirements. For standard orders, you’re looking at $5.8-8 per kg, while bulk purchases over 8,800 kg drop to $2.5-3.5 per kg.

In cylinder form, you’ll pay around $0.458 per cubic foot for a 24-cubic-foot steel cylinder. Storage system costs increase with pressure ratings, especially for specialized high-pressure systems (300-500bar).

Can Nitrous Oxide Be Recycled or Reclaimed After Industrial Use?

Yes, you can recycle and reclaim nitrous oxide through several efficient reclamation processes. Major facilities like Linggas in China demonstrate successful recycling of 6,000 tons annually.

You’ll find multiple methods available, including decomposition units, gas capture systems, and thermal dissociation technologies. These processes guarantee reduced environmental impact by preventing N₂O release, which is 300 times more potent than CO₂ as a greenhouse gas.

Which Countries Are the Largest Producers of Industrial Nitrous Oxide?

You’ll find that China and the United States dominate industrial nitrous oxide production scale, accounting for approximately 80% of global output. China leads with over 400 million metric tons CO2e annually, while India ranks third.

The EU maintains strict regulatory oversight of its production facilities. Following these are Brazil and Russia, with significant industrial capacity. These top producers are closely monitored due to nitrous oxide’s environmental impact and industrial importance.

How Long Can Nitrous Oxide Be Stored Before It Degrades?

You’ll find that nitrous oxide has no inherent shelf life limitation when properly stored. It won’t degrade chemically over time in an intact container.

Storage temperature impacts are vital though you must maintain stable conditions to prevent pressure fluctuations. In food-grade steel or aluminum tanks, you can store N2O for up to 30 years with proper maintenance and regular safety assessments. Upright positioning and ventilated storage are indispensable.

What Alternatives Are Being Developed to Replace Nitrous Oxide in Industry?

You’ll find several alternatives replacing nitrous oxide across industries. In medical settings, you can use sevoflurane or regional anesthesia techniques.

For automotive applications, you’re seeing a shift in the direction of electric vehicles and hybrid systems. Alternative refrigerants and CO₂-based systems are becoming prevalent in food processing.

Emission reduction strategies include mechanical dispensing systems and nitrogen-based solutions. These alternatives help meet environmental regulations while maintaining industrial efficiency.