You’ll find nitrous oxide (N2O) serving critical functions across multiple industries beyond medicine. It’s utilized in automotive performance tuning for power gains of 100-200+ horsepower, food preservation systems for flash-freezing and texture amelioration, semiconductor manufacturing for creating silicon dioxide layers, and metal fabrication for controlled oxidation processes. While these applications drive market growth, they’ve contributed to a 25% increase in atmospheric N2O levels since pre-industrial times. Understanding its broader industrial impact reveals complex technological and environmental considerations.

Applications in Modern Automotive Engineering

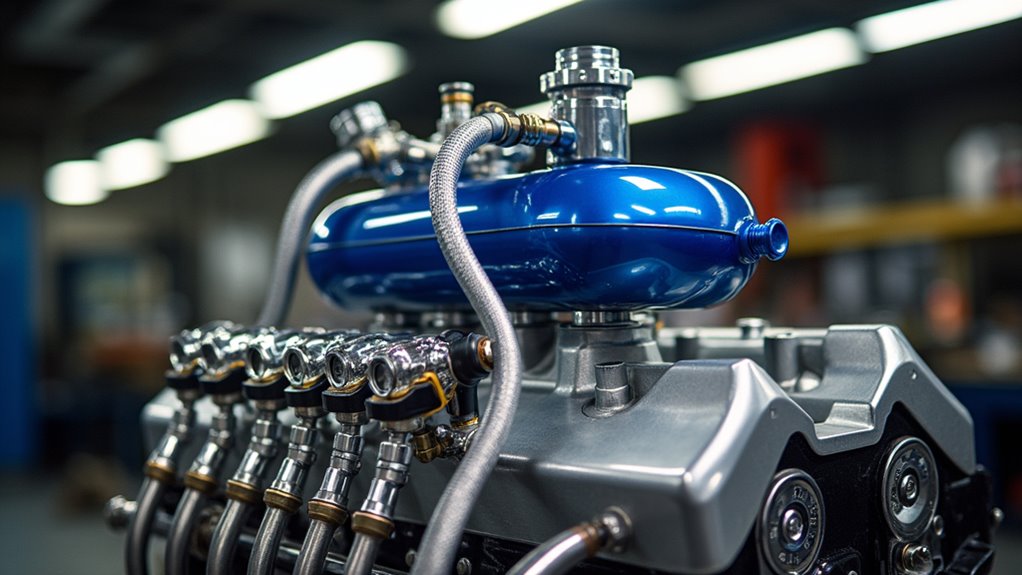

While nitrous oxide has diverse industrial applications, its role in automotive engineering centers on delivering substantial power increases through controlled oxygen enrichment. When you engage a nitrous system, N₂O decomposes into oxygen and nitrogen, enabling rapid fuel burn rates and instant power gains of 100-200+ horsepower through aftermarket tuning capabilities. The power surge duration typically lasts 10-15 seconds before deactivation is necessary to prevent engine damage.

Racing performance advantages include tactical power application for overtaking and hill climbs, though you’ll need proper engine reinforcement to handle increased pressures. The nitrous oxide tank requires high-strength materials to safely contain the pressurized liquid N2O. Modern electronic control units guarantee precise N₂O delivery timing, while expanded adoption in marine and off-road markets demonstrates the technology’s versatility across high-torque applications. A system purge release before activation ensures optimal liquid nitrous oxide delivery by removing trapped air and gaseous nitrous oxide.

You’ll find two primary system configurations: dry systems that inject N₂O separately from fuel, and wet systems that introduce both simultaneously.

Food Industry Processing and Preservation

As modern food processing evolves, nitrous oxide serves multiple critical functions in preservation, texture improvement, and packaging applications. You’ll find this versatile compound bolstering food packaging efficiency through inert atmosphere creation and surface sterilization, while simultaneously improving product quality and shelf life. Molecular gastronomy experts have pioneered innovative culinary applications since its discovery. Professional chefs rely on its properties as an odorless propellant for creating perfect aerosol whipped creams.

Flash-freezing systems utilize N2O to minimize ice crystal formation, preserving both nutrients and texture integrity. Flavor enhancement occurs through controlled atmosphere maintenance, protecting volatile compounds during storage. Packaging applications harness N2O for oxygen displacement, reducing oxidation and extending product longevity. Innovative chefs use N2O to create unique culinary textures through rapid expansion and dissolution in fats. Texture modification processes employ N2O to create stable foams and aerated products, from whipped cream to specialty desserts.

This technology’s implementation reduces food waste while optimizing resource utilization, making it invaluable for modern food processing operations seeking sustainable preservation methods.

Electronics Manufacturing and Semiconductor Production

Through advanced semiconductor manufacturing processes, nitrous oxide plays an integral role in creating high-performance microelectronic components. You’ll find it essential in thermal oxidation, where it forms high-quality silicon dioxide layers that enhance transistor performance and prevent current leakage between components.

In chemical vapor deposition, it combines with silane to deposit precise dielectric films, pivotal for modern chip fabrication. Semiconductor facilities store N₂O in specialized tanks designed to maintain 750 psi pressure levels. The process enables the production of electrical insulators critical for microelectronic transistor functionality. Ultra high purity nitrous oxide with 99.999% composition is required for these precision manufacturing processes.

N₂O’s adaptability extends to plasma process optimization during selective etching and ion implantation, enabling precise pattern definition and material modification. You can rely on it for creating mixed oxide films with diverse metals, supporting advanced memory devices and sensors.

Furthermore, it’s becoming increasingly valuable in environmentally conscious manufacturing, as it generates fewer greenhouse gases than traditional oxidizing agents while maintaining superior electrical performance.

Industrial Metal Fabrication Processes

Moving from semiconductor fabrication to metal processing, nitrous oxide’s unique chemical properties improve different industrial metal fabrication operations. You’ll find N₂O playing a pivotal role in controlled oxidation environments, particularly during chemical etching techniques and lattice repair methods adapted from semiconductor manufacturing. Content verification is continuously required to maintain optimal N₂O usage in these processes. Since N2O is a long-lived greenhouse gas, careful emissions monitoring during metal fabrication is essential to minimize environmental impact.

N₂O participates in redox reactions that bolster surface treatments while preventing unwanted oxide formation during high-temperature processes. The gas supports annealing atmospheres where precise oxidation control is indispensable for stress relief and defect repair. At elevated temperatures, N₂O becomes reactive and enhances metal surface modification processes. Advanced CVD techniques utilize N₂O-derived compounds for uniform metal coating deposition. Safety systems mirror semiconductor standards, with specialized leak detection and high-purity gas handling protocols.

The integration of N₂O in metal fabrication demonstrates how semiconductor industry practices can successfully transfer to traditional manufacturing processes.

Environmental Impact and Market Growth

While industrial applications of N₂O continue expanding, the gas’s environmental footprint raises serious concerns across agricultural and chemical sectors. You’ll find N₂O’s atmospheric concentration has reached 336 ppb in 2022, 25% above pre-industrial levels, driven by a 78% surge in commercial nitrogen fertilizer use between 1980-2020. With annual emissions exceeding 10 million metric tons, industrial growth shows no signs of slowing.

The nitrogen cycle disruption from chemical fertilizers and manure has amplified N₂O emissions by 40% since 1980. Top emission-producing countries like China, India, and the US lead global N₂O output. What’s particularly alarming is the ozone layer risk, as N₂O has become the largest ozone-depleting substance. The chemical industry’s nitrogen-intensive processes, combined with agricultural expansion, have created a challenging scenario where market growth directly correlates with increased emissions. Practical solutions exist that could achieve 40% emission reductions through targeted abatement strategies. Without intervention, these emissions could jeopardize the 1.5°C global warming pathway and accelerate ozone depletion.

Frequently Asked Questions

Can Nitrous Oxide Be Safely Stored in Residential Garages?

You shouldn’t store nitrous oxide in residential garages due to significant safety risks. Proper ventilation requirements are rarely met in typical garage settings, creating dangerous gas accumulation hazards.

Without adequate airflow and temperature control (10-30°C), you’re facing potential explosion hazards from pressure buildup. Furthermore, most residential garages lack required safety features like fire-resistant barriers and emergency response systems. Consider professional storage facilities instead for safe handling.

What Personal Protective Equipment Is Required When Handling Industrial Nitrous Oxide?

When handling industrial nitrous oxide, you’ll need thorough PPE including splash-resistant goggles and a NIOSH-approved full-face respirator for concentrations above 25 ppm. You must wear insulated, chemical-resistant gloves and cold-resistant clothing to prevent cryogenic burns.

Guarantee proper ventilation in your workspace to maintain oxygen levels and prevent gas accumulation. Always follow OSHA 1910.134 respiratory protection guidelines and regularly inspect all PPE for damage.

How Long Does Industrial-Grade Nitrous Oxide Remain Stable in Storage?

You’ll find that industrial-grade nitrous oxide remains stable indefinitely when you maintain proper storage temperature requirements between 10-30°C. Your cylinder maintenance procedures are indispensable – keep containers upright, monitor pressure levels (45-55 bar for ambient storage), and guarantee low humidity conditions.

You should regularly check for valve integrity and pressure relief systems. If you notice pressure fluctuations or temperature excursions outside these ranges, you’ll need to assess the gas stability immediately.

Are There Specific Transportation Licenses Needed for Nitrous Oxide Distribution?

Yes, you’ll need specific licenses for nitrous oxide transportation and distribution. For bulk transportation licensing, you must obtain an ADR driver certificate and designate a Safety Advisor. Your company requires supplier/retailer licenses based on local industrial distribution regulations.

If you’re handling over 2 kg commercially, you’ll need full ADR certification. For air transport, you’ll also need special PHMSA permits if using non-standard cylinders.

What Are the Emergency Protocols for Handling Nitrous Oxide Leaks?

If you detect a nitrous oxide leak, you’ll need to immediately implement emergency shutdown protocols by stopping gas flow at the source. Guarantee proper ventilation procedures are activated to disperse gas concentrations, and evacuate all untrained personnel through designated routes.

You must restrict access to the affected area and deploy PPE-equipped response teams. Don’t forget to monitor system pressure every 15 minutes during containment and document all response actions taken.